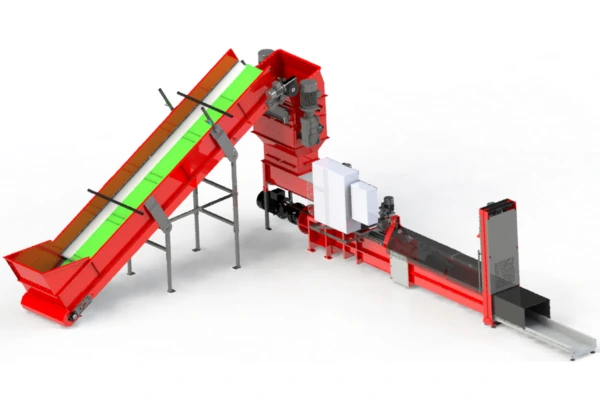

AUGER COMPACTION & DEWATERING SYSTEMS

Auger Compaction Systems & De-Watering Solutions

Kernic Systems offers cost effective auger compaction and de-watering products to integrate with your existing waste & recycling systems.

EPS Compactors or “Densifiers” are designed to handle low to high volumes of foam waste generated in various packaging applications. Whether you are dealing with EPS, EPP, XPS, or EPE, Kernic Systems has a solution available for you.

The same style of auger compaction is also effectively utilized in de-watering and product destruction applications. Contact Kernic Systems today to find out more!

LABOR SAVING

Our screw compactor solutions for foam densification and dewatering save valuable time and money for your operation

PRODUCT DESTRUCTION

Auger compaction systems are excellent at destroying damaged or expired products, draining liquids while preparing containers for recycling.

RETURN ON INVESTMENT

An exceptional ROI from low equipment cost, high value of recycled material, combined with labor savings = $$$ in your pocket.

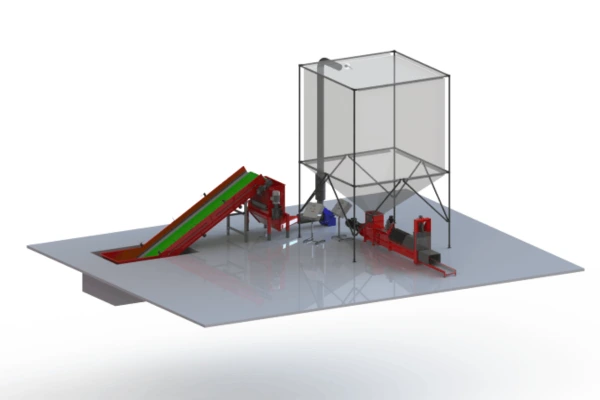

Densifiers & De-Watering Compaction Solutions

Kernic Systems offers a full range of cost-effective densifier and de-watering solutions to suit the needs of your business.

Compaction & Dewatering solutions offered by Kernic Systems are of the highest quality; they deliver long life, superior reliability, and quality compaction. Our equipment meets current safety levels and delivers the lowest total cost of ownership (TCO).

Compacting Solutions for All Applications

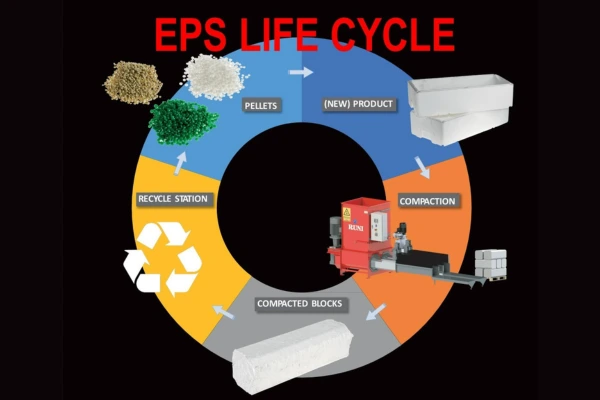

Densifying waste packaging materials like EPS or EPP not only diverts it from landfill, but it also proves quite valuable in block format. Densifier systems offer an exceptional return on investment (ROI) as it streamlines the logistical costs behind transporting waste packaging material with an impressive 50:1 compactiong ratio. Densifiers are commonly used in distribution centers (specifically in furniture and appliance distributors), grocery stores, MRF’s, and more!

LDPE DRYING SOLUTIONS

Kernic Systems offers LDPE drying solutions for plastics recycling facilities. LDPE, commonly used as shrink wrap is washed and dried before it can be remade into extruded pellets for reforming. The auger system from RUNI dries LDPE with compression instead of centrifugal force, requiring considerably less energy.

FOAM DENSIFIERS

EPS a.k.a styrofoam is notoriously challenging to recycle when the correct equipment is not available. No longer. The EPS foam densifiers from RUNI utilize pre-crushers and auger screws to condense EPS foam into easy to handle and transport blocks to continue their journey to reuse and recycle instead of the landfill.

DE-WATERING SOLUTIONS

The perfect solution for beverage manufacturers who generate quantities of make-ready waste and reject products. Draining these beverages can be time consuming and sending them to the landfill is expensive. The RUNI de-watering auger compaction systems remove liquid and process containers to be ready for recycling.

AVAILABLE MODELS

SK240 FOAM DENSIFIER

The SK240 from RUNI A/S takes various designations of foam, mostly commonly EPS, and makes it into manageable blocks for further recycling.It has a capacity of approx. 75 kg of EPS/hour.

It has a recommended annual throughput of 30-50 tonnes, making it the perfect medium volume EPS foam densifier for:

- Large Retailers

- Small/Medium Distribution Centers

- Manufacturing Facilities

- Recycling Centers

SK240 DEWATERING

The SK240 dewatering system from RUNI A/S takes beverage and product destruction to the next level. The auger screw and compaction force crushes the products (bottles, cans, etc.), draining the liquid into a reservoir underneath to be pumped away, while the reject material is deposited into bins for further recycling.

It has an hourly capacity of 7,000 alu cans, 5,000 Tetra-Pak, or 5,000 PET bottles making it the perfect medium volume dewatering/product destruction solution for:

- Beverage Packagers

- Grocery Distributors

- Recycling Centers

SK370 FOAM DENSIFIER

The SK370 from RUNI A/S takes various designations of foam, mostly commonly EPS, and makes it into manageable blocks for further recycling.It has a capacity of approx. 200 kg of EPS/EPP/EPE/PUR or XPS per hour.

The SK370 has multiple recommended options and is the go-to machine for large foam packaging recycling. It is the perfect large volume foam densifier for:

- Large Retailers

- Large Distribution Centers

- Appliance Delivery Stores & Centers

- Recycling Centers

Contact Us Today!

News

Vertical Baler for Upcycled Textile Program

Balers - vertical baler for Upcycled Textiles vertical baler for Upcycled Textiles Donated clothing finds new life with this Bramidan B6030 Vertical Baler! A customer in Eastern Ontario who operates a donation program for used or upcycled clothing needed a solution to manage the high volumes of textiles they received through their drop-off bin program. Kernic Systems was able [...]