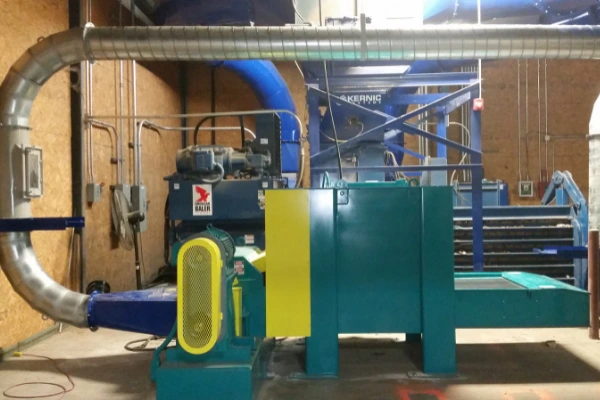

HORIZONTAL CONVEYOR FEED SHREDDERS

High Capacity Horizontal Conveyor Feed Shredders

Kernic Systems offers horizontal conveyor feed shredders to improve your recycling systems. Conveyor feed shredders are easily adapted to air conveying systems, and are designed to manage a wide variety of waste generated by your business.

Horizontal conveyor feed shredders are the perfect way to recover scrap generated in the corrugated, folding carton, and tissue industries. By integrating these units into your existing scrap removal systems, you can take your material recovery process to the next level.

HIGH THROUGHPUT

Depending on the size of your horizontal conveyor feed shredder and the material being shredded, the maximum throughput is up to 14,000 lbs. per hour of material.

LONG SERVICE LIFE

From easily changed shredding teeth and blades, to stable and heavy duty welded construction, our horizontal conveyor feed shredders have an extremely long service life.

SIMPLE INTEGRATION

With various configurations and plenums available to suit your shredding needs, these units are easily integrated into your existing scrap and trim removal systems.

High Throughput Conveyor Feed Shredders

Kernic Systems offers a full range of Horizontal Conveyor Feed Shredders to shred a wide variety of materials.

Shredders offered by Kernic Systems are of the highest quality; they deliver long life, superior reliability, and quality shredding. Our shredders meet current safety levels and deliver the lowest total cost of ownership (TCO).

Efficient and Effective Shredding

Horizontal Conveyor Feed Shredders are engineered and manufactured to shred a wide variety of waste, including, corrugated sheet waste, set-up boxes, folding carton scrap, paper cores, roll slab, tissue logs and much more. This versatility makes them common in the corrugated, paperboard and tissue industries.

Horizontal Conveyor Feed Shredders are designed to easily integrate into a new or existing pneumatic scrap-handling system. Shredder sizes range from 40” to 110” wide.

Features of our horizontal conveyor feeds shredders include:

FOLDING CARTON PLANTS

Commonly used in folding carton plants, conveyor feed shredders are perfect for handling waste cartons and paperboard produced during the folding carton manufacturing process. They are easily integrated into your existing pneumatic conveying systems and have low Total Cost of Ownership (TCO).

CORRUGATED BOX PLANTS

The right tool for the job, the horizontal conveyor feed shredder is designed to handle scrap materials deemed waste during the manufacturing process. Increase productivity and efficiency of your recycling process by integrating the conveyor feed shredder into your existing scrap removal system today.

VIDEOS

Contact Us Today!

News

Vertical Baler for Upcycled Textile Program

Balers - vertical baler for Upcycled Textiles vertical baler for Upcycled Textiles Donated clothing finds new life with this Bramidan B6030 Vertical Baler! A customer in Eastern Ontario who operates a donation program for used or upcycled clothing needed a solution to manage the high volumes of textiles they received through their drop-off bin program. Kernic Systems was able [...]