DP 16 DRUM CRUSHER

DP16 Drum Crusher

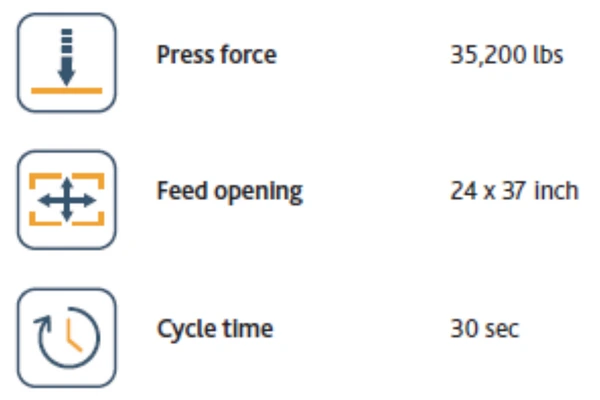

The DP16 Drum Crusher from Bramidan is an industry leading, small profile machine. With a press force of 35,200 lbs., and a simple yet efficient design, this unit makes short work of your standard 55 gallon drums and smaller. This model operates on three phase 480V power supply and offers up to 90% compaction of steel or plastic drums.

This machine offers the lowest in-class noise levels and is incredibly simple to use. It’s simple and safe operation comes standard with dual-channel safety monitoring that meets and exceeds all North American Safety Standards. Start saving money on your drum recycling and disposal costs with this simple to Take your waste management practices to the next level with this simple, small, and powerful unit!

- Up to 90% compaction

- Handles drums up to 55 gallons

- Not intended for drums with explosive contents or residues.

- Spikes in press plate puncture the drum and remove air

- Optional drip tray available to catch residuals.

- High degree of safety

- Interlock system prevents the motor from running unless the door is closed

- Compressed drums are easy to stack and store

- Meets ANSI and OSHA standards

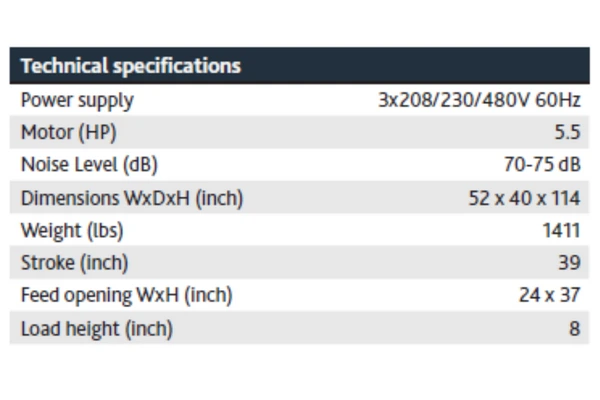

Press Force

35,200 lbs.

Waste Volume

Small / Medium / Large

Feed Opening Size

WxH (in.) 24″ x 37″

Cycle Time

30 seconds

Stroke

39 inches

Noise Level

70-75 dB

Press Force

35,200 lbs.

Waste Volume

Small – Medium – Large

Feed Opening Size

WxH (in.) 24″ x 37″

Cycle Time

30 seconds

Stroke

39 inches

Noise Level

70-75 dB

Product Features

Product Highlights

SALES

PARTS & SERVICE

SALES

PARTS & SERVICE

Who uses our Vertical Balers?

Industry Manufacturing

Retail Stores

Distribution Centers

Health Sector

Recycling Centers

Waste Handling

Fast Food Chains

Public Sector

Contact Us Today!

News

Vertical Baler for Upcycled Textile Program

Balers - vertical baler for Upcycled Textiles vertical baler for Upcycled Textiles Donated clothing finds new life with this Bramidan B6030 Vertical Baler! A customer in Eastern Ontario who operates a donation program for used or upcycled clothing needed a solution to manage the high volumes of textiles they received through their drop-off bin program. Kernic Systems was able [...]