B5W VERTICAL BALER

B5 Wide Vertical Baler

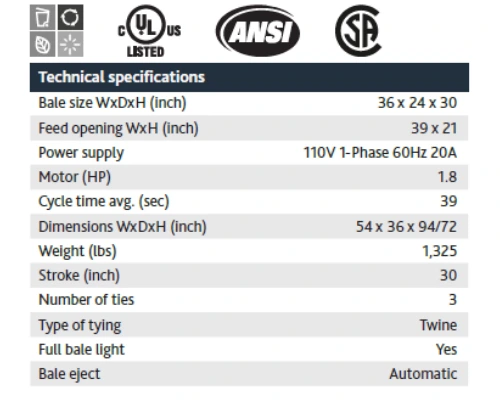

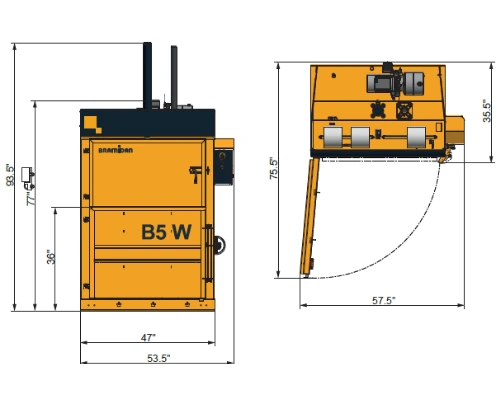

The B5 Wide Vertical Baler from Bramidan is the industry leading small profile, wide-fill (39″) opening machine. With a press force of 11,000 lbs., retainer dogs to keep material compressed, and a frontal tie system, this machine is the perfect solution to your waste handling needs. This model operates on single phase 110V power supply (dedicated 20A circuit required), offering a simple to install baling option.

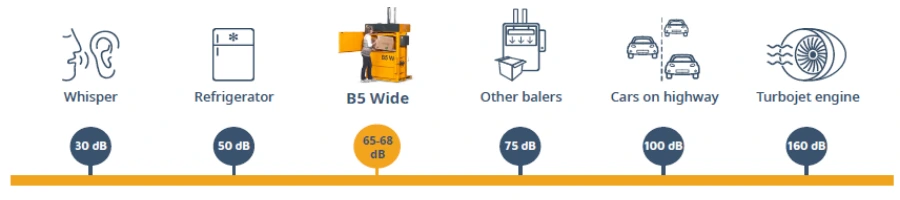

This machine offers the lowest in-class noise levels and is incredibly simple to use. It’s simple and safe operation comes standard with an automatic full light indicator and two-handed automatic bale eject. The B5 W comes standard with the BRA-IN monitoring system from Bramidan that tracks bale output, sends notifications when bales are ready to be tied off, and more! Take your waste management practices to the next level with this simple, small, and powerful unit!

- High capacity – large output

- Wide feed opening (39 in.)

- Retainer dogs hold down compacted waste

- Auto-eject system

- Store and refill bale cord in front

- Single-phase power pack

- Meets ANSI and OSHA standards

Press Force

11,000 lbs.

Waste Volume

Small

Feed Opening Size

WxH (in.) 39″ x 21″

Bale Size

WxDxH (in.) 36″x 24″x 30″

Bale Weight

175 – 290 lbs.

Waste Types

Cardboard, Paper, Plastic

Press Force

11,000 lbs.

Waste Volume

Small – Medium

Feed Opening Size

WxH (in.) 39″ x 21″

Bale Size

WxDxH (in.) 36″ x 24″ x 30″

Bale Weight

175 – 290 lbs.

Waste Types

Cardboard, Paper, Plastic

Product Features

Safe & Efficient

Users safely eject finished bales using the two-hand automatic bale ejection system. ANSI Z245.5, UL and CSA Compliant

Financing Available

Kernic Systems offers financing rates through a preferred third-party lender. Take your recycling and waste management processes to the next level, all for one low monthly fee.

Product Highlights

Connect, monitor and analyze your equipment

With the BRA-IN monitoring solution you can make faster and better decisions while reducing your costs of operation.

SALES

PARTS & SERVICE

SALES

PARTS & SERVICE

Who uses our Vertical Balers?

Industry Manufacturing

Retail Stores

Distribution Centers

Health Sector

Recycling Centers

Waste Handling

Fast Food Chains

Public Sector

Contact Us Today!

News

Horizontal Full-Eject Balers for Streamlined Recycling

Balers - Horizontal Full-Eject Horizontal Full-Eject Balers for Streamlined Recycling Streamline your recycling process with Horizontal Full-Eject Manual Tie Balers from Maren Engineering Corporation. Optimized for multiple materials, our balers ensure superior reliability, quality bales, and adhere to the highest safety levels, providing you with the lowest total cost of ownership. Capable of handling everything from OCC, [...]